For some weird reason my seatpost managed to creep down incrementally over several rides. I had not loosened it, so I had no reason to suspect anything was wrong. I just started to notice that the seat felt low. After a couple of days off the bike I hopped on to ride the morning commute and the change was finally obvious. I hoped off again by the side of the road, pulled the multi-tool out of my seat pack and raised the seat.

In the course of fine-tuning -- not to say fiddling with -- my position, I had made at least a couple of height marks on the post. Friction in the frame had obscured these scratches, but I could discern a couple. I chose the one that put the seat highest, about three millimeters higher than the other mark I could find.

Right away the seat felt kind of high, and slightly crooked. I have a lot of trouble lining my seat up with the top tube. That's one reason I purposely avoid messing with it, making a mysteriously loose seat binder even more strange. I figured it was good enough to get to work on.

On the ride home that evening I really felt the height. I felt knee pain, crotch discomfort, loss of power, and foot alignment problems. When I lowered the seat three (3) millimeters, all that went away.

The "science" of bike fit is complicated by the fact that humans are flexible and elastic and we fidget around on our bikes. Fit is not so much a matter of exact position to the millimeter, but rather finding the range in which a particular rider can operate most efficiently for their style of riding. In almost any dimension, most riders have a centimeter or two of leeway. However, as soon as you go beyond that range, you feel as if you're off by a huge amount. Thus I did not notice as the seat crept down, even as it crept well below the optimum position. I only noticed after I'd been completely away from the bike for a couple of days. Then it was obvious. Then, when I raised the seat again, I went that tiny bit beyond my functional range and started to feel all kinds of symptoms that might drive a less experienced rider to question multiple systems on the bike: cleat alignment, saddle choice or angle, and padding in the shorts, just to name a few. Yet it all stemmed from three millimeters of seatpost height.

The tiny amount, three millimeters, might seem to give some credence to the micro-engineering bike fitters. I say avoid getting too neurotic. Once I was back in range I could sit farther back on the saddle, which returned me to my familiar contact points. I could go three millimeters lower and probably feel fine as well. I just have an inferiority complex about my long torso and short legs, so I hate to bury the seatpost any more than I have to. Hence my choice of the higher height mark in the first place when I discovered the seat was too low.

The tiny increment does give you something to think about if you're chasing down an elusive lack of comfort or power.

Once you do get a position dialed in, measure every possible dimension to help you recover that position if the bike is ever disassembled or to reproduce the fit when getting a new bike. Pick measurements that don't depend on other things being equal between your old bike and your new one. For instance, if you drop a plumb line from the nose of the saddle to see how far it falls behind the bottom bracket shell, make sure you're using the same saddle on both bikes or have compensated for any difference. A wider saddle will put you in a different position, probably farther forward, than a narrower one. Measure every wacky thing you can think of before you disrupt the position on a bike that fits you well.

Some advice and a lot of first-hand anecdotes and observations from someone who accidentally had a career in the bike business.

Monday, June 27, 2011

Thursday, June 23, 2011

Between one thing and another...

Even now I'm stealing time from something else to slap up a hasty post on the blog.

Distractions include my continuing attempts to learn to play a musical instrument late in life:

And cartooning, obviously.

And cartooning, obviously.

Distractions include my continuing attempts to learn to play a musical instrument late in life:

And cartooning, obviously.

And cartooning, obviously.I've also spent considerable computer time trying to get the new wearable camera and my old computers to play nicely together. Still working on that. Meanwhile, shooting began on the bike safety TV segment.

Ryan from Wolfeboro Community Television prepares to shoot action footage of a cyclist in the wild.

Ryan from Wolfeboro Community Television prepares to shoot action footage of a cyclist in the wild.

Ryan from Wolfeboro Community Television prepares to shoot action footage of a cyclist in the wild.

Ryan from Wolfeboro Community Television prepares to shoot action footage of a cyclist in the wild.The repair shop continues to dish up time-consuming challenges. Yesterday's involved a Campagnolo 10-speed shifter. My most recent manual for Ergopower may go as late as 2000. I estimated this shifter at about 2007. Campy's website does not provide the usual metric ton of PDFs for the grunts who actually fix things to download. I had to settle for an exploded diagram from the spare parts catalog.

You want your shifter? I got your shifter right here. Explooooooded view of Campy Record Ultra 10-speed shifter guts.

You want your shifter? I got your shifter right here. Explooooooded view of Campy Record Ultra 10-speed shifter guts.

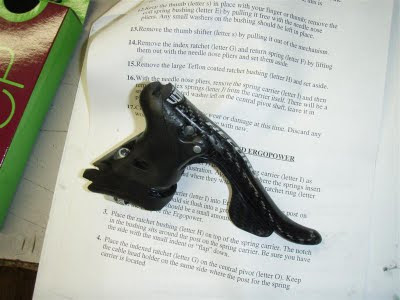

The reassembled shifter sitting on the outdated manual. Campy being Campy, not only do the parts more or less go together the same way, some specific parts actually still work in shifters almost 10 years newer. Shimano? Are you listening? Of course not.

The reassembled shifter sitting on the outdated manual. Campy being Campy, not only do the parts more or less go together the same way, some specific parts actually still work in shifters almost 10 years newer. Shimano? Are you listening? Of course not.

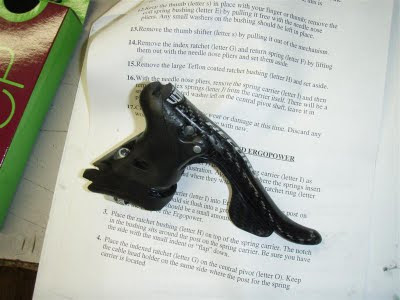

The flip side of the reassembled shifter.

The flip side of the reassembled shifter.

And now I'm late leaving for work. Nothing new there. It's the down side of having a lot of interests.

You want your shifter? I got your shifter right here. Explooooooded view of Campy Record Ultra 10-speed shifter guts.

You want your shifter? I got your shifter right here. Explooooooded view of Campy Record Ultra 10-speed shifter guts. The Road Map to Pieces

The reassembled shifter sitting on the outdated manual. Campy being Campy, not only do the parts more or less go together the same way, some specific parts actually still work in shifters almost 10 years newer. Shimano? Are you listening? Of course not.

The reassembled shifter sitting on the outdated manual. Campy being Campy, not only do the parts more or less go together the same way, some specific parts actually still work in shifters almost 10 years newer. Shimano? Are you listening? Of course not. The flip side of the reassembled shifter.

The flip side of the reassembled shifter.Parts inside there are worn, so I would not rate the shifter 100 percent reliable. The rider is going to get a new one, since this one was part of a salvaged gruppo put on her bike several years ago. This rider is 5'5". The cranks she inherited are 175s. So the problems go further than just an old, tired shifter. Since Campy goes to 11 now, the remaining 10-speed shifters are surprisingly affordable.

And now I'm late leaving for work. Nothing new there. It's the down side of having a lot of interests.

Tuesday, June 14, 2011

Slick little video about urban bike infrastructure

A friend on Facebook shared this video by a cyclist who was ticketed for NOT riding in a bike lane. The stunt work shows real commitment and durability. It also raises questions about the effectiveness of helmets, since the guy takes all his stunt falls without one. He has excellent technique. Hard to say if he would fare as well if the crash came as a complete surprise. But let's not lapse into the endless helmet debate.

Thursday, June 09, 2011

Oh Boy, Helmet Cam

My new helmet cam arrived yesterday. Quality Bicycle Products was dumping the Contour HD 1080p for a reduced price, so I went ahead and used some accumulated shop credit. I figure if nothing else I can use video from it on the bike safety TV show project that's crawling ever so slowly forward.

It turns out both my computers are too stupid to show HD video. Unless I figure out how to shoot something they can eat, I have just bought a really expensive laser pointer for the cats. That's okay. I love my cats. And the TV producer who is working on the safety show with me can probably use the good stuff. I just don't have a ton of time to work on everything I need to work on right now.

Once I get everything running right I hope to put up a few vids of favorite bits of local rides.

It turns out both my computers are too stupid to show HD video. Unless I figure out how to shoot something they can eat, I have just bought a really expensive laser pointer for the cats. That's okay. I love my cats. And the TV producer who is working on the safety show with me can probably use the good stuff. I just don't have a ton of time to work on everything I need to work on right now.

Once I get everything running right I hope to put up a few vids of favorite bits of local rides.

Another day, another piece of weird, home-built crap

People will try all kinds of sketchy rigs to get their handlebars higher. With quill stems they could raise it way above the maximum height line. Supposedly that increases the risk that the stem might bend or break or that the steerer tube of the fork could crack because the stem no longer reinforced it at the end of the threaded part. Sure, it's possible, but has anyone ever seen it happen? I haven't. I don't advise raising the stem to ridiculous heights. I'm just saying that people who do it seem to avoid any negative consequences.

People will try all kinds of sketchy rigs to get their handlebars higher. With quill stems they could raise it way above the maximum height line. Supposedly that increases the risk that the stem might bend or break or that the steerer tube of the fork could crack because the stem no longer reinforced it at the end of the threaded part. Sure, it's possible, but has anyone ever seen it happen? I haven't. I don't advise raising the stem to ridiculous heights. I'm just saying that people who do it seem to avoid any negative consequences.With threadless headsets, the home hobbyist has to get more creative. We've all seen the bikes with the bar ends sticking straight up. That was the 1990s version of the ten-speed with the drop bars turned upside down.

The owner of this bike assembled his custom handlebar out of PVC. It isn't even fastened together securely. If the rider hits a bump while leaning on that top section it will quickly become the bottom section. If the rider even leans heavily on it, it will move.

This setup takes its place alongside the sheet-metal home-built pant guard a man made for himself, which was basically just a meat-slicer blade going around next to his ankle, and the home-made chopper fork a kid welded and installed on his bike without a headset at all.

Wednesday, June 01, 2011

Help Wanted

Wanted: Bicycle Mechanic. Must have spent the last three decades working for crap money, keeping up with the endless flow of weird mechanical bullshit spewed out by the bike industry. The ideal candidate will be able to remember basic specifications of bikes and parts from the 1970s to the near future and be able to analyze and troubleshoot bizarre new designs on sight.

Work load will vary from nonexistent to ridiculous within minutes.

Applicant must be a highly intelligent, creative problem solver who is also enough of an idiot to get stuck in this business.

Pay somewhat exceeds minimum wage.

Apply today!

Work load will vary from nonexistent to ridiculous within minutes.

Applicant must be a highly intelligent, creative problem solver who is also enough of an idiot to get stuck in this business.

Pay somewhat exceeds minimum wage.

Apply today!

Subscribe to:

Posts (Atom)